60SArtificial response

30MinInternal technical reply

24HourFree programme

Feed grain size≤0.5mm

Throughput10-260t/h

【Application area】Cement grinding, new materials, dry mortar, ceramics, rubber, petroleum exploitation, aerospace and so on

【Applicable material】Cement, calcium-based powder, silica powder, titanium dioxide powder, iron ore, limestone, quartzite, construction waste, iron ore, gold ore, etc.

7*24 hours free consultation hotline

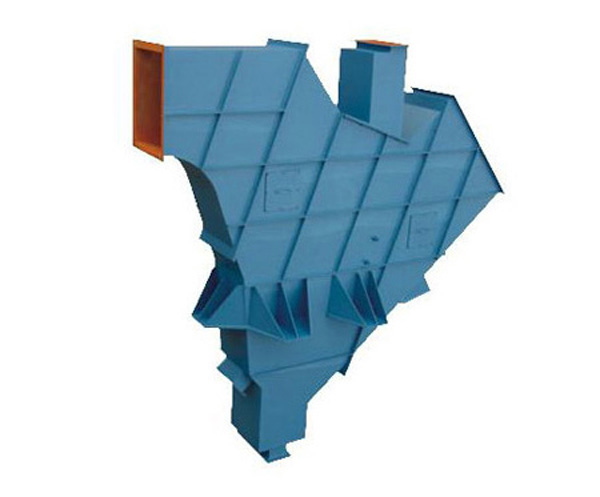

151959771961. T-Sepax high-efficiency three-phase separator adopts two-stage separation and three-stage dispersion, which can collect coarse particles from mixed powder into coarse powder cones in the first-stage classification area of coarse powder (d > 150um), medium-coarse powder (60um < d < 150um) and fine powder. The guide vane and the straight cage rotor are completed in the annular area. Because the coarse particles are pre-separated and the interference of coarse particles is eliminated, the classification accuracy is high and the separation efficiency is over 85%.

2. Compared with centrifugal, cyclone and rotor separators with similar sizes, T-Sepax high-efficiency separator has much higher output, so it is more suitable for large-scale production. Advanced and reasonable structure allows the air flow rate, output and feed rate of flour selection to vary in a large range without affecting the flour separation efficiency, and its classification performance is very stable.

3, the principle of classification is advanced. Combining with many kinds of flour separation principles, the aerodynamic analysis method is used to optimize the design of the whole flow field. The resistance of the equipment is significantly reduced, the flour separation efficiency is higher, and the energy saving and consumption reduction are very obvious. The rotor of the separator is equipped with a national invention patent eddy current rectifier. The air flow in the rotor only rises and does not rotate relative to the rotor, so the air flow field on the surface of the classifying ring is uniform and stable. The relative error of the air flow at any place is less than 5%. When the air flow enters the rotor, the momentum moment reduces the thrust to the rotor, saves the driving power and reduces the wear and tear.

4, the classifier adopts stepless speed regulation. Fineness adjustment is convenient, sensitive and reliable, and wide range of adjustment.

5, we re optimized the spatial scope of the selected area and upgrading area. T-Sepax high-efficiency separator has compact structure and small volume. It can be used in any closed-circuit grinding system composed of grinding equipment. It is suitable for open-flow mill, single-closed-circuit mill and double-closed-circuit mill, especially for semi-final grinding and final grinding system with roller press.

6. Wear-resistant materials are used in the parts of powder separator, such as sprinkler, cyclone, snail horn, guide vane and rotor, and the wear rate is very low. The new lining of manganese lining is adopted to effectively prolong the service life of the lining.

7. The new design scheme of the bearing seal under the main shaft effectively solves the two major problems of dust entering the bearing and oil leakage, and effectively prolongs the service life of the bearing.

8. When designing the foundation of the separator, the principle of mechanical vibration reduction is adopted, so that the resonance frequency between the separator and the foundation is not close to the natural frequency of the separator, which overcomes the resonance phenomenon and fundamentally solves the vibration problem of the separator, which has puzzled the manufacturer for a long time.

9. Double interlock air valve is used in coarse powder pipe, medium-coarse powder pipe and fine powder pipe, which greatly reduces the air leakage rate of the system and overcomes the defect of large dust emission during the operation of the old separator.

Creating value for customers is the consistent persistence of Lafa, customer demand-oriented, customer satisfaction is the significance of our efforts to adhere to. 365 days all-weather to provide you with a sound after-sales service, customer success is our unchanged goal, is willing to become a mentor in your career, mutual success.

Years of experience in R & D and manufacturing of flour milling machinery

Constantly updating technology to produce new equipment

Energy conservation and environmental protection is in line with state regulations.

Actively developing intelligent Era

Perfect after-sale service system

Copyright @ Nanjing Lafa Environmental Engineering Co., Ltd Hotline:025-86118737